Oxy-fuel torches are a staple in metalworking industries, widely used for cutting, welding, brazing, and heating applications. The efficiency and safety of an oxy-fuel torch depend heavily on the proper setup and maintenance of its components. Whether you’re a seasoned professional or a hobbyist, mastering the complete setup tips for oxy-fuel torch efficiency can make a significant difference in your results and resource consumption.

This article explores everything from selecting the right components and adjusting the flame to maintaining equipment and following essential safety protocols. We also cover optimal setting for oxy acetylene cutting torch to ensure precision, safety, and fuel economy.

Understanding the Oxy-Fuel Torch System

Before diving into setup tips, it’s crucial to understand the components involved in an oxy-fuel system:

- Fuel Gas Cylinder: Typically acetylene or propane.

- Oxygen Cylinder: Supplies the oxidizing agent.

- Regulators: Control the pressure of gases from the cylinders.

- Hoses: Transport gases from cylinders to the torch.

- Torch Handle: Holds the mixing chamber and valves.

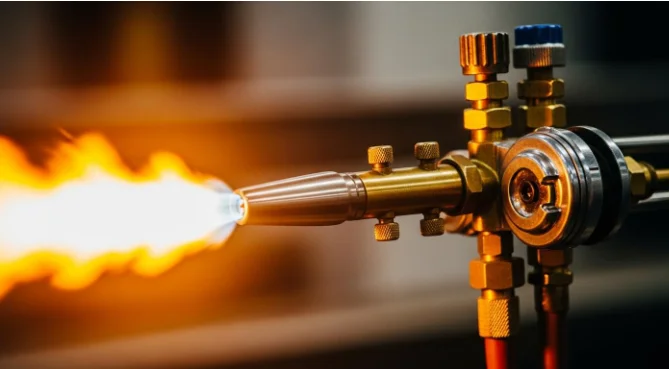

- Tips/Nozzles: Where the gas exits and ignites, varies based on the application (cutting, welding, brazing, or heating).

Proper setup of each part ensures maximum torch performance and safety during operation.

1. Cylinder Preparation and Inspection

Start by placing your oxygen and fuel cylinders in an upright position and securing them properly to prevent tipping. Inspect both cylinders for any visible damage or contamination. Never use oil or grease on valves or fittings as these can ignite when combined with oxygen under pressure.

- Open the valves slowly.

- Always stand to the side while opening cylinder valves.

- Use the correct regulator designed specifically for the gas.

For more detail on flame types and adjustments, refer to this guide on complete setup tips for oxy-fuel torch efficiency.

2. Regulator Setup

Attach the regulators to the cylinders using the correct threading. Oxygen regulators have right-hand threads, while acetylene regulators use left-hand threads.

Best Practices:

- Ensure all connections are clean and tight.

- Use Teflon tape only if manufacturer-approved.

- Open the cylinder valve slowly and read the pressure gauge to check supply levels.

Once both regulators are securely attached, adjust them to the appropriate pressure levels for your torch tip and job type.

3. Hose Management

Use color-coded hoses for clarity: red for fuel gas and green for oxygen. Check for any leaks, cracks, or wear before each use. Hoses should be long enough to give you maneuverability but not so long that they become a trip hazard or difficult to manage.

Tips:

- Never use damaged hoses.

- Keep hoses away from hot metal or flames.

- Use flashback arrestors and check valves to prevent reverse gas flow or flame back into hoses.

4. Torch Handle and Tip Selection

Choose the correct torch handle and tip size based on the type of metal and thickness you’re working with. Smaller tips are ideal for thin materials, while larger tips are needed for thicker metals or heavy-duty heating.

Attach the tip securely and inspect it for obstructions. A clogged tip can lead to irregular flames or flashbacks.

5. Adjusting the Flame for Efficiency

Ignite the torch using a spark lighter—never use matches or open flames. Begin by opening the fuel valve slightly, lighting the gas, and then slowly opening the oxygen valve to adjust the flame.

There are three main types of flames:

- Carburizing Flame (excess fuel): Good for certain brazing applications.

- Neutral Flame (balanced oxygen and fuel): Ideal for most cutting and welding jobs.

- Oxidizing Flame (excess oxygen): Used for specific applications like cutting steel.

For optimum efficiency and safety, you should aim for a neutral flame in most cases. This ensures that neither fuel nor oxygen is wasted and that the metal is not contaminated during welding or cutting.

6. Pressure Settings for Oxy-Acetylene Cutting

One of the most critical aspects of setup is setting the correct pressures for your torch.

Typical starting pressures:

- Oxygen: 20–40 PSI (depends on tip size and cutting thickness)

- Acetylene: 5–10 PSI (never exceed 15 PSI)

These values can vary depending on the torch model and job requirements. Always consult your torch manufacturer’s manual or follow standard cutting charts to get the precise setting for oxy acetylene cutting torch.

Important Note: Always light the fuel gas first, then introduce oxygen. When shutting off, close the oxygen valve first, followed by the fuel valve.

7. Flashback Arrestors and Check Valves

Install flashback arrestors and check valves at both the torch and regulator ends. These safety devices prevent the dangerous backflow of gases and reduce the risk of explosion or torch damage due to flashback.

Make sure to test these devices periodically and replace them as needed.

8. Maintenance Tips for Long-Term Efficiency

An efficient oxy-fuel setup isn’t just about proper initial configuration—it also involves routine maintenance:

- Clean torch tips regularly to prevent carbon buildup and maintain consistent flame patterns.

- Inspect hoses, valves, and regulators for wear and tear.

- Store equipment properly, away from moisture and direct sunlight.

- Calibrate regulators periodically for pressure accuracy.

Well-maintained tools improve fuel economy and reduce the chances of accidents.

9. Common Mistakes to Avoid

- Using mismatched components (wrong regulator or torch tip)

- Over-pressurizing fuel gas beyond safe limits

- Igniting torch with high gas flow

- Using damaged hoses or non-approved accessories

- Forgetting to bleed lines after use

Avoiding these mistakes will improve safety and prolong equipment life.

10. Safety Practices to Maximize Torch Efficiency

- Wear appropriate PPE: gloves, flame-resistant clothing, goggles or face shield.

- Keep fire extinguishers nearby.

- Work in well-ventilated spaces.

- Follow local and OSHA safety guidelines.

- Never leave the torch unattended while lit.

Efficient operation isn’t just about fuel—it’s also about operating safely and confidently.

Conclusion

Efficient operation of your oxy-fuel torch begins with a solid understanding of the entire system—from gas cylinders to torch tips. Following the complete setup tips for oxy-fuel torch efficiency ensures not only consistent performance but also enhanced safety and lower operational costs.

Adjusting gas pressures correctly, maintaining your equipment, and understanding the proper setting for oxy acetylene cutting torch are all crucial for achieving clean cuts, smooth welds, and extended tool life.