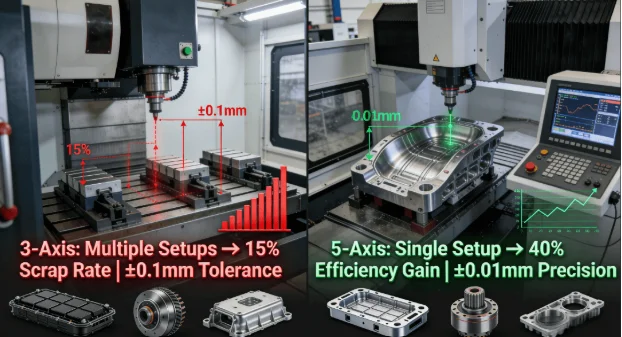

3-axis vs 5-axis CNC machining comparison for automotive manufacturing showing 40% efficiency gain and ±0.01mm precision improvement

Introduction

The automotive industry is constantly undergoing radical changes, and with the increasing use of electric vehicles, it has become a challenge for car makers to weigh light weighting requirements with structural robustness. The requirements of light weighting components to increase the range of electric vehicles, as well as requirements of complex components such as battery trays and electric motor housing, have made it clear that conventional machining technology has limitations, with 3-axis CNC machining being a culprit due to its inability to perform multiple setups, resulting in accumulated errors and design limitations due to increased cycle times.

The following points highlight how 5-axis machining technology has emerged as a revolutionizing factor that achieves single-setup precision and light weighting and accelerates electric vehicle development at a dramatic pace with increased efficiency and design capabilities.

What Are the Core Limitations of Traditional Machining in Modern Automotive Production?

Conventional 3-axis CNC machining works well with more straightforward components, but there are considerable bottlenecks when it is considered necessary within current automotive requirements. Three areas are discussed, which impact precision and efficiency.

1. Error Accumulation with Multiple Conformations

Car manufacturers find that parts usually undergo several fixturing operations in order for the machining of the automobile parts to be complete. Every time the part is moved, errors are introduced in terms of alignment, therefore resulting in tolerancing. A good example is when a transmission housing undergoes three separate machining operations. The resulting automobile might experience problems with the bore locations being out of position. According to the Society of Manufacturing Engineers, these errors can lead to a 15% scrap rate.

2. Geometric Constraints and Inefficiencies

3-axis movement impedes the use of complex shapes by the tools of 3-axis machines. This hinders the designer by compelling him to divide his component into simpler shapes. This naturally increases the assembly process. Moreover, the machining process will become extraordinarily slow due to the operation of the ball-end mill at a small step-over value with the aim of retaining the surface finish. This poses a challenge regarding the lightweight design required by an electric car.

3. Impact on Production Efficiency and Costs

Multiple configurations increase the cycle times dramatically, along with an increase in labor costs. To elaborate, take the case of a brake caliper. While performing conventional machining, it might require 45 minutes involving multiple fixtures. In contrast, it may involve only one operation with 5-axis technology. These inefficiencies also extend into other areas, such as tool life and even energy consumption, where research reveals 3-axis machining might incur operational costs 30% higher in contrast to more advanced alternatives. These considerations lie behind the growing unsuitability of traditional approaches in the rapidly changing automotive industry.

How does 5-axis machining finally allow unprecedented design freedom for lightweighting?

5-axis machining adds two rotational axes to allow dynamic orientation of the tool with new opportunities for high-strength, lightweight components. This section explores how it contributes to design innovation.

l Dynamic Toolpath Control for Complex Shapes: Enabling machines to access the workpiece from any direction possible makes 5-axis machines useful in turning organic designs like biomimetic designs or thin-walled channels. This enables the designer to design an algorithm for topology optimization, which removes unnecessary material. As an example, a suspension arm can be created with lattice structures inside, cutting over 40% of the material but retaining its bearing capacity, which is essential for EV design.

l Improved Stability for Thin-Walled Components: In 5-axis machining, shorter and stiff cutting tools absorb less vibration, which is important in the machining of thin-walled parts, as in the case of EV battery enclosures that have walls thinner than 1.5mm. In such a case, the machining process avoids any deformation and wall thickness variation since the cutting tools are optimally engaged, following geometric dimensions that conform to standards such as the ASME Y14.5 standard.

l Case Example: Lightweighting Success: A case in point is the use of an EV chassis part made of aluminum, in which the 5-axis machining resulted in a weight reduction of 50% in comparison with the traditionally machined part. This single-machine operation removed the need for other processing steps with 35% faster overall processing time.

5-axis machining workflow for electric vehicle battery trays showing lightweighting design and leak-proof sealing surface achievement

What Role Does Single-Setup Precision Play in Electric Vehicle Components?

The integrity of components for EVs like battery trays and motors relies upon accuracy, which 5-axis machines provide by performing tasks in a single setup. This topic will be discussed in more detail below.

1. Ensuring Leak-Tight Sealing Surfaces

Battery trays need highly plano sealing surfaces that prevent coolant or liquid from entering the trays. With 5-axis machining, complete large-format trays can be machined within a single clamping process with a flatness accuracy of 0.1 mm. This technique eliminates alignment errors associated with multi-setup machining processes, which are directly related to Leak Protection. For instance, best practices for professional 5-axis automotive manufacturing incorporate common datum definition for seal quality during production.

2. Precision for Critical Features such as Bearing Holes

Components like motor housings require accuracy at the micron level regarding bearing seats or mounting points. The single setup machining process guarantees that the datum remains constant throughout the process, thus ensuring that the positional tolerance is within ±0.01mm. Such accuracy increases the efficiency of the e-drive technology by preventing possible failures due to minute deviations.

3. Integration with Quality Assurance

“In-process process control through in-machine probing integrates perfectly with the high-precision processing achievable within a single set-up to offer real-time feedback,” writes the company. Solutions that comply with standards IATF 16949 also integrate such checks to guarantee that each workpiece satisfies the relevant specs automatically. Such an approach clearly emphasizes the role of 5-axis technology in fulfilling the zero-defect strategy for the car industry.

Beyond the Machine: What Advanced Processes Guarantee Micron-Level Accuracy?

To attain this precision on a consistent basis, more than 5-axis machining is required. This section describes the supporting factors.

- In-Process Measurement and Adaptive Control: Machining can be done with real-time dimension verification with the use of technologies such as on-machine probing. This is achieved by the use of probes whose information is used in adaptive control systems that adjust the machining parameters in cases of thermal drift or tool wear to ensure that the tolerance is maintained at no more than ±0.005mm. Examples of such technologies are found in ISO 9001 certified manufacturing shops that have closed-loop systems that can self-correct any deviations.

- Environmental and Machine Calibration: Climate-controlled environments, along with volumetric compensation through the use of laser trackers, reduce the effects of thermal expansion and machine geometric errors. Such considerations are highly important for larger parts, such as battery trays, for which dimensional stability during extended machining operations is essential. IATF 16949-certified suppliers would normally implement such processes, thereby stressing the importance of identifying suppliers with such sophisticated process controls.

- Data Traceability and Compliance: Data traceability by means of MES archives every machining parameter, ensuring compliance with automotive standards. Root cause analysis and improvements, crucial elements of a smart manufacturing environment, also become possible.

How Manufacturers Can Leverage 5-Axis Solutions for a Quick Return on Investment?

Investment in 5-Axis technology provides high ROI due to operational efficiency. This section will enumerate the benefits of 5-Axis technology.

1. Fixturing and Tooling Costs Reduction

Single-set machining reduces the need for a number of custom fixtures, which results in a reduction of up to 40% in terms of design and manufacturing cost in the prototype stages. For instance, a car mold insert requires a single fixture, whereas it required seven before.

2. Shorter Cycle Times and Higher Throughput

Because of operations integration, 5-axis machines minimize downtime and parts handling. In a case study, machines resulted in efficiency gains for a complex part from 18 hours to 11 hours, an increase of nearly 40%. Such fast processing enables just-in-time manufacturing, essential in the EV industry for quick responses to the marketplace.

3. Reduced Scrap Rates and Lifecycle Cost Savings

Improved accuracy helps minimize scrap, and Cpk ratios frequently exceed 1.67. Also, component reduction helps reduce assembly, and this means that overall savings can be made in the long run. Manufacturers who want to implement change can consider teaming with those who have expertise in 5-axis machining services.

What the Future May Look Like for Intelligent, Data-Driven Automotive Manufacturing

The development of 5-axis machining is moving towards embracing Industry 4.0 and predictive and adaptive manufacturing. Innovations are some of the trends in this topic.

l Digital Twins and Simulation: Digital twin technology enables the creation of digital copies of the machining process in order for optimisation to take place prior to production. Simulations include predictions regarding tool wear and collisions.

l Internet of Things and Predictive: Sensors in 5-axis CNC machines monitor parameters such as spindle loading and temperature, enabling predictive maintenance. Predictions of machine failures prior to their occurrence also reduce unplanned machine shutdowns, thereby improving machine life.

l Integration with Smart Factory Ecosystems: Integrating 5-axis machines with MES and ERP systems makes it easier for real-time production tracking and energy saving. Such integration makes 5-axis machines a precursor for sustainable manufacturing in the automotive industry, which follows the global automotive sustainability plan.

Conclusion

5-axis CNC machining has been absolutely invaluable in helping solve current issues in the car manufacturing industry, but its worth will be even more pronounced in the new age of electric vehicles. Greater precision, flexibility, and efficiency will be ensured through single-operation machining, which will be the harbinger of a new age of smart manufacturing in the industry.

FAQs

Q1: What are the benefits of 5-Axis Machining over 3-Axis Machining in automotive components?

A: These are primarily related to being able to machine complicated geometries in a single setup, thus avoiding cumulative errors. This is more important in lightweighting components as it relates to electric vehicles.

Q2: How is deformation during machining minimized when creating thin-walled automotive components?

A: Deformation is controlled with customized fixture design, adaptive toolpath, and other methods such as trochoidal machining, which distributes cutting pressures evenly. This allows it to maintain tolerance at ±0.1mm when dealing with thin walls.

Q3: What type of certifications would the automotive parts maker require from the precision automotive components supplier?

A: Key certifications achieved include ISO 9001 for Quality Management Systems and IATF 16949 for the Auto sector.

Q4: Can 5-axis machining help enhance the leak-tight seal of the EV battery tray sealing surface?

A: It allows for smoothness within 0.1 mm by machining the sealing surfaces as a single unit with zero discrepancies and therefore improves leakage safety.

Q5: How long is the average payback period for an investment in five-axis machining technology for the automobile industry?

A: These values for ROI typically range between 12 and 18 months and depend mostly on cycle time reductions and part reduction. More in-depth analysis may be conducted in consultation with a solutions expert.

Author Bio

The author is a precision manufacturing expert at LS Manufacturing, a company which serves engineers and researchers by helping in complex parts challenges in aerospace, medical, and automotive sectors. The company is qualified in IATF 16949 and AS9100D, ensuring high-quality delivery through the latest technology. To gain further information, get in touch with them to have a free project review and DFM analysis. Turn your ideas into a cost-effective reality.